CM Polyimide Aluminum Coating Film

Specification

CM Polyimide film formed by sputtering metal aluminum, then develops thin aluminum layer, with one side insulation, the other side high conduct electricity. It not only has the performance of excellent heat resistant, mechanical, chemical stability, radiation resistant, and self-extinguishing, but also EMI shielding, high thermal conductivity. It can be applied in radiation resistant of inner space suit, EMI shielding, seal material, electromagnetic shielding tape, flexible etching wire.

Features:

Corrosion resistant, environment-friendly with halogen free, highest UL-94 flammability rating:V-0.

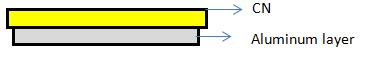

Structure:

Parameters

Property | Unit | CM25 | Test Method | |

PI Thickness | μm | 25±3 | ASTM D374 | |

Thickness of Aluminum layer | A | 400-800 | ASTM D374 | |

Width | mm | 520 | ASTM D374 | |

Tensile Strength | MD | Mpa | ≥150 | ASTM D882 |

TD | Mpa | ≥145 | ASTM D882 | |

Elongation | MD | % | ≥45 | ASTM D882 |

TD | % | ≥45 | ASTM D882 | |

Surface Density | g/㎡ | ≤35 | ASTM D1505 | |

The above data are for reference only.

Pictures

Application

The Polyimide Aluminum Coating Film used for Radiation resistant of inner space suit, EMI shielding, seal material, electromagnetic shielding tape, flexible etching wire.