Plastic is a kind of plastic that can be molded under certain conditions, but the shape of the product can remain unchanged after processing Materials with high molecular weight organic compounds as basic components . Plastics are generally divided into general plastics and engineering according to their use characteristics.

There are two types of plastics. General plastics refer to the plastics with large output, good formability and low price, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), etc. Engineering plastics refer to the plastics with excellent mechanical properties and high temperature resistance, which can be used in engineering, including peek, PI, PES, etc

Polyimide (PI) is a kind of special engineering plastics with high temperature resistance and good mechanical properties and dimensional stability. It can be divided into two categories: aromatic polyimide and aliphatic polyimide. Generally speaking, the polyimide refers to aromatic polyimide. The existence of its bicyclic structure makes the heat resistance very good. It can be used for a long time above 200 ℃. The mechanical and electrical properties are also outstanding in engineering plastics.

In the research and production of flexible copper clad laminate, especially in the process of lamination, the composite laminate is used to prepare flexible copper clad laminate

Membrane plays an important role. Two kinds of polyimide resins were selected for the composite membrane, in which thermoplastic polyimide was used as adhesive, while ordinary polyimide was used to improve heat resistance and dimensional stability. The two polyimide resins complement each other and each has its own advantages, so that the overall performance of the composite membrane is excellent.

In the actual production process, the corresponding requirements for two kinds of polyimides are also put forward

It is necessary to control the thermoplastic polyimide layer between 1-5 μ m, and the minimum glass transition temperature should be about 200 ℃. For ordinary polyimide, it needs high heat resistance, good dimensional stability and mechanical strength, and low moisture absorption. In this way, the polyimide composite film can have good comprehensive properties and is suitable for making high-performance flexible copper clad laminate under hot pressing conditions.

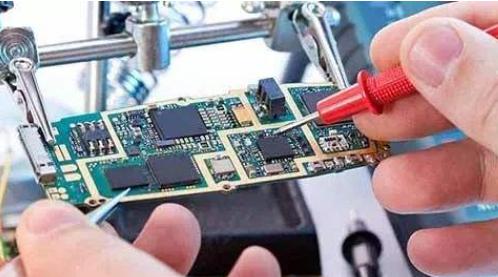

The full name of copper clad laminate material is copper clad laminate material, also known as the base material, is made of resin and reinforcement

Material and copper foil hot pressed. After a series of processes, such as etching and punching, the printed circuit is produced

PCB, which can be applied to a series of electronic products such as computers, mobile phones, digital cameras, is closely related to people's life.http://www.china-polyimide.com